NM series light weight insulating bricks

Date:2016-12-13 / Popularity:

Temperature grade: 1250℃-1750℃

Product Description

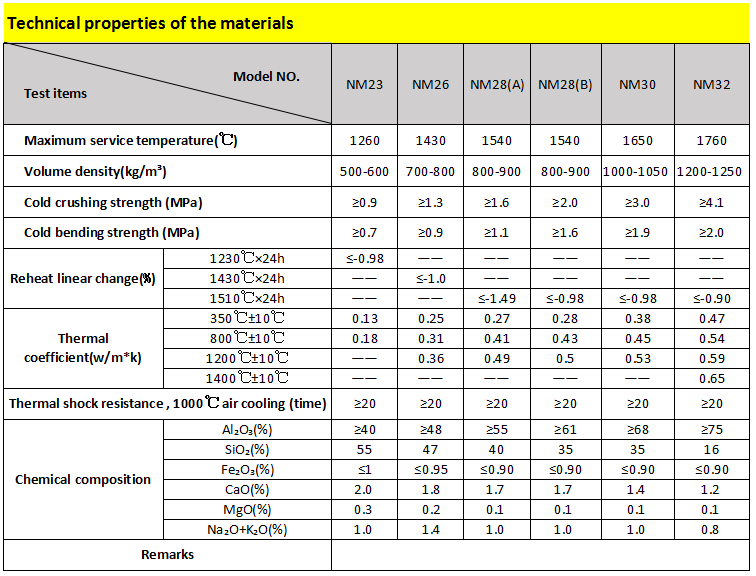

NM series light weight insulating bricks are a new type of deformable light weight insulating bricks which is developed based on the combination of domestic and international new fire-resistant raw materials and chemical binding agents to deal with different situations the original ZQ series of light weight bricks faced while being used in domestic petrochemical hydrogen transformation furnaces, ethylene cracking furnaces, synthetic ammonia primary reformer, building materials drawer furnace and roller kilns, etc. NM series of light weight insulating bricks' chemical contents include master ingredients of Al2O3 and SiO2, controlled ingredients of Fe2O3 and minor ingredients of TiO2, CaO, MgO and Na2O+K2O. Every different grade would strictly use different organic stuffing materials which would be burnt down in the production process. Use vacuum squeezing for continuous automatic production through the high temperature burning process in high-temperature tunnels to produce high-quality light weight insulating bricks with even and uniform micro-pore structure (able to reduce the thermal transmission coefficient of materials), high softening temperature at load and low linear change.

Characteristics

Low thermal conductivity: ensure very good heat insulating effect, which allows thinner furnace wall thickness and reduces the load weight of the device.

Low content of foreign substances: high-purity fire-resistant clay and Al2O3 contain very low quantity of ferrous and other low-melting temperature alkali metal. Therefore, the material has high fire-resistant temperature and could maintain decent performance under a recovering environment.

Accurate overall dimensions: Machine processing is used for the aim of precise dimensions for all six surfaces to accelerate laying speed, ensure thin, tidy and consistent brick gap (standard shape ±0.5mm), tidy and consistent, high building body strength and good globality.

Low linear variation rate and high thermal shock stability: ensure reduced deformation (crack, break or peeling off) when every brick is used as the thermal surface fire-resistant lining, improving the globality of the bricks and extending the overall life of the lining.

Application of materials

They could be used as the back lining insulating layer in the hot surface refractory lining or other refractory materials. Applied in petrochemical hydrogen transformation furnaces, cracking furnaces, sulfur burning furnaces, chemical synthetic ammonia primary transformation furnaces, coal gas generating furnaces, even heat furnaces, annealing furnaces, drawer kilns, roller furnaces and other similar industrial thermal equipment.

Brick type

In addition to bricks of standard size (230*114*65mm), NM series insulating bricks could be provided to be processed into irregular bricks. Especially large bricks could be formed by binding together two or more than two big bricks.

Product Description

NM series light weight insulating bricks are a new type of deformable light weight insulating bricks which is developed based on the combination of domestic and international new fire-resistant raw materials and chemical binding agents to deal with different situations the original ZQ series of light weight bricks faced while being used in domestic petrochemical hydrogen transformation furnaces, ethylene cracking furnaces, synthetic ammonia primary reformer, building materials drawer furnace and roller kilns, etc. NM series of light weight insulating bricks' chemical contents include master ingredients of Al2O3 and SiO2, controlled ingredients of Fe2O3 and minor ingredients of TiO2, CaO, MgO and Na2O+K2O. Every different grade would strictly use different organic stuffing materials which would be burnt down in the production process. Use vacuum squeezing for continuous automatic production through the high temperature burning process in high-temperature tunnels to produce high-quality light weight insulating bricks with even and uniform micro-pore structure (able to reduce the thermal transmission coefficient of materials), high softening temperature at load and low linear change.

Characteristics

Low thermal conductivity: ensure very good heat insulating effect, which allows thinner furnace wall thickness and reduces the load weight of the device.

Low content of foreign substances: high-purity fire-resistant clay and Al2O3 contain very low quantity of ferrous and other low-melting temperature alkali metal. Therefore, the material has high fire-resistant temperature and could maintain decent performance under a recovering environment.

Accurate overall dimensions: Machine processing is used for the aim of precise dimensions for all six surfaces to accelerate laying speed, ensure thin, tidy and consistent brick gap (standard shape ±0.5mm), tidy and consistent, high building body strength and good globality.

Low linear variation rate and high thermal shock stability: ensure reduced deformation (crack, break or peeling off) when every brick is used as the thermal surface fire-resistant lining, improving the globality of the bricks and extending the overall life of the lining.

Application of materials

They could be used as the back lining insulating layer in the hot surface refractory lining or other refractory materials. Applied in petrochemical hydrogen transformation furnaces, cracking furnaces, sulfur burning furnaces, chemical synthetic ammonia primary transformation furnaces, coal gas generating furnaces, even heat furnaces, annealing furnaces, drawer kilns, roller furnaces and other similar industrial thermal equipment.

Brick type

In addition to bricks of standard size (230*114*65mm), NM series insulating bricks could be provided to be processed into irregular bricks. Especially large bricks could be formed by binding together two or more than two big bricks.

Above data is theoretical value

Edit:JUNYAO

Quality-oriented

Quality-oriented