Burner in petrochemical industrial furnace

Date:2016-12-13 / Popularity:

Brief introduction of the material

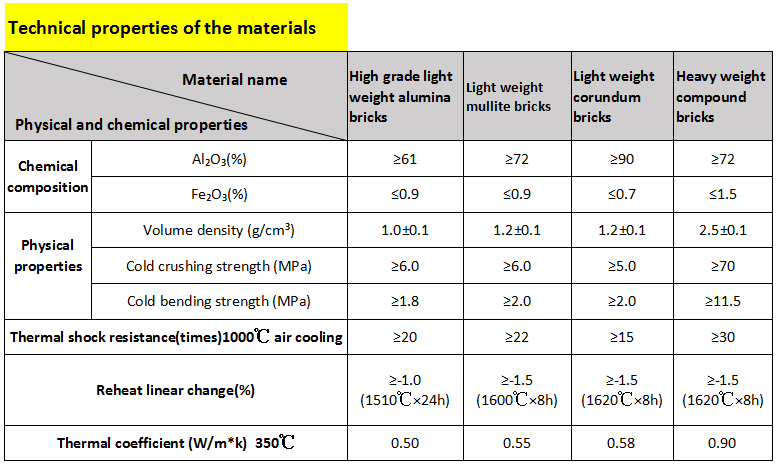

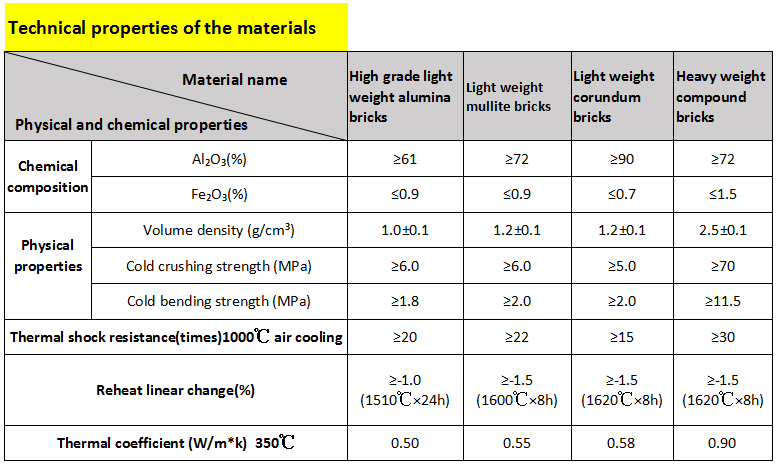

NM series nozzle bricks are a new type of refractory materials developed by our company based on referring to foreign manufacturing technologies of nozzle bricks and combining new type of domestic refractory raw materials. They are an improvement to traditional manufacturing technologies. It has such characteristics as high fire-resistance, flushing-resistance and good thermal shock stability. It is the best selection of materials for use in petrochemical ethylene cracking burners. This series of nozzle bricks include light weight bricks and heavy weight bricks which are produced with different manufacturing technologies, respectively. Heavy weight nozzle bricks are produced using vibrating hydraulic formation and high-temperature baking. Using master composites Al2O3 and SiO2, controlled composite Fe2O3, plus other minor composites, through raw materials selection, particle matching, introduction of compound super fine powders, such outstanding features as high temperature resistance, flushing resistance and good thermal shock stability could be realized. Light weight nozzle bricks are produced using high-tonnage static pressing machine for one-shot feeding and formation as well as high-temperature tunnel kiln burning. They are suitable for industrial kiln burners which the working temperature is between 1000-1650℃.

Above data is theoretical value

NM series nozzle bricks are a new type of refractory materials developed by our company based on referring to foreign manufacturing technologies of nozzle bricks and combining new type of domestic refractory raw materials. They are an improvement to traditional manufacturing technologies. It has such characteristics as high fire-resistance, flushing-resistance and good thermal shock stability. It is the best selection of materials for use in petrochemical ethylene cracking burners. This series of nozzle bricks include light weight bricks and heavy weight bricks which are produced with different manufacturing technologies, respectively. Heavy weight nozzle bricks are produced using vibrating hydraulic formation and high-temperature baking. Using master composites Al2O3 and SiO2, controlled composite Fe2O3, plus other minor composites, through raw materials selection, particle matching, introduction of compound super fine powders, such outstanding features as high temperature resistance, flushing resistance and good thermal shock stability could be realized. Light weight nozzle bricks are produced using high-tonnage static pressing machine for one-shot feeding and formation as well as high-temperature tunnel kiln burning. They are suitable for industrial kiln burners which the working temperature is between 1000-1650℃.

Above data is theoretical value

Edit:JUNYAO

Quality-oriented

Quality-oriented