Chemical stuffing materials (non-metal ceramics)

Date:2016-12-13 / Popularity:

Product Category

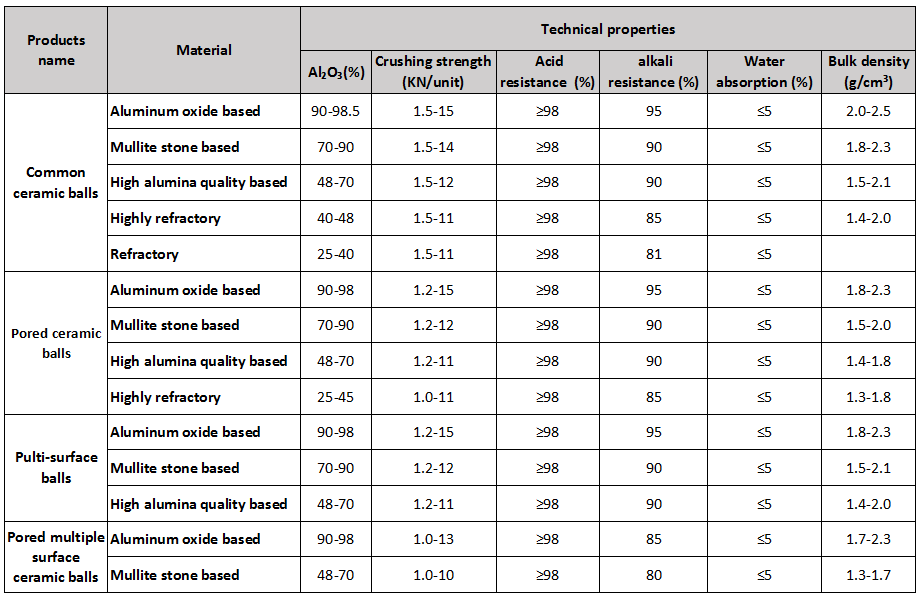

Non-metal ceramic chemical stuffing materials are divided into two types: ceramic balls and ceramic rings; ceramic balls include aluminum oxide, mullite, high alumina and refractory ceramic balls in terms of chemical composition. Based on overall shape, they are divided into pored ceramic balls, pored multiple surface ceramic balls, multi-surface balls and common ceramic balls. Items:∮3mm、∮4mm、∮5mm、∮6mm、∮8mm、∮10mm、∮12mm、∮13mm、∮15mm、∮19mm、∮25mm、∮32mm、∮35mm、∮40mm、∮45mm、∮50mm、∮60mm、∮75mm.

Brief Introduction of the material

Aluminum oxide balls, mullite ceramic balls, high alumina ceramic balls, ordinary inertia ceramic balls (refractory balls) use natural minerals as main raw materials, plus industrial aluminum oxide powders and a small portion of additives through a series of raw material treatment, dry power high pressure or dry powder forming and high temperature burning at the temperature range of 1350-1650℃. They have such features as corrosion resistance, high mechanical strength, low dielectric loss and good chemical stability, etc. Its main crystal phase is mullite and a certain amount of glass phase.

Aluminum oxide balls, mullite ceramic balls, high alumina ceramic balls, ordinary inertia ceramic balls (refractory balls) are mainly used in equipment regarding petrochemical fertilizer, transformation furnace, synthetic tower, refinery hydrogenation reactor, platinum reforming, hydrogen generation, sulfur and gas separation equipment. Use ceramics with good chemical stability as the stuffing material to increase the distribution points of gas or liquid.

Above data is theoretical value

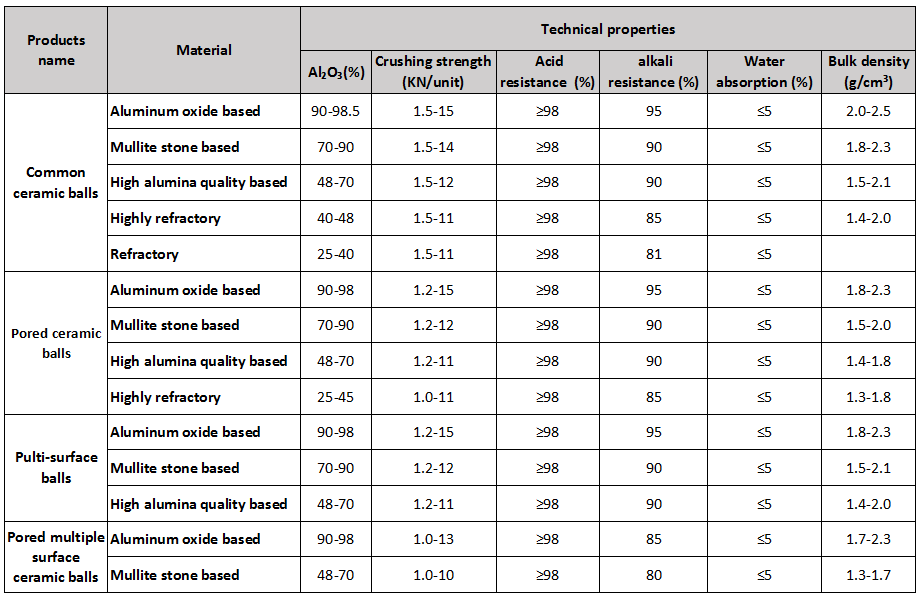

Non-metal ceramic chemical stuffing materials are divided into two types: ceramic balls and ceramic rings; ceramic balls include aluminum oxide, mullite, high alumina and refractory ceramic balls in terms of chemical composition. Based on overall shape, they are divided into pored ceramic balls, pored multiple surface ceramic balls, multi-surface balls and common ceramic balls. Items:∮3mm、∮4mm、∮5mm、∮6mm、∮8mm、∮10mm、∮12mm、∮13mm、∮15mm、∮19mm、∮25mm、∮32mm、∮35mm、∮40mm、∮45mm、∮50mm、∮60mm、∮75mm.

Brief Introduction of the material

Aluminum oxide balls, mullite ceramic balls, high alumina ceramic balls, ordinary inertia ceramic balls (refractory balls) use natural minerals as main raw materials, plus industrial aluminum oxide powders and a small portion of additives through a series of raw material treatment, dry power high pressure or dry powder forming and high temperature burning at the temperature range of 1350-1650℃. They have such features as corrosion resistance, high mechanical strength, low dielectric loss and good chemical stability, etc. Its main crystal phase is mullite and a certain amount of glass phase.

Aluminum oxide balls, mullite ceramic balls, high alumina ceramic balls, ordinary inertia ceramic balls (refractory balls) are mainly used in equipment regarding petrochemical fertilizer, transformation furnace, synthetic tower, refinery hydrogenation reactor, platinum reforming, hydrogen generation, sulfur and gas separation equipment. Use ceramics with good chemical stability as the stuffing material to increase the distribution points of gas or liquid.

Above data is theoretical value

Edit:JUNYAO

Quality-oriented

Quality-oriented