High-temperature wear-resisting insulating bricks

Date:2016-12-13 / Popularity:

Corundum and mullite series high-temperature refractory materials are suitable to be used in various kiln equipment (electromagnet air sintering kilns, magnet nitrogen sintering kilns, petrochemical synthetic ammonia one-two transformation furnace, carbon oxide burning furnace, sulfur burning furnace, coking furnace, carbon black furnace and claus furnace, etc).

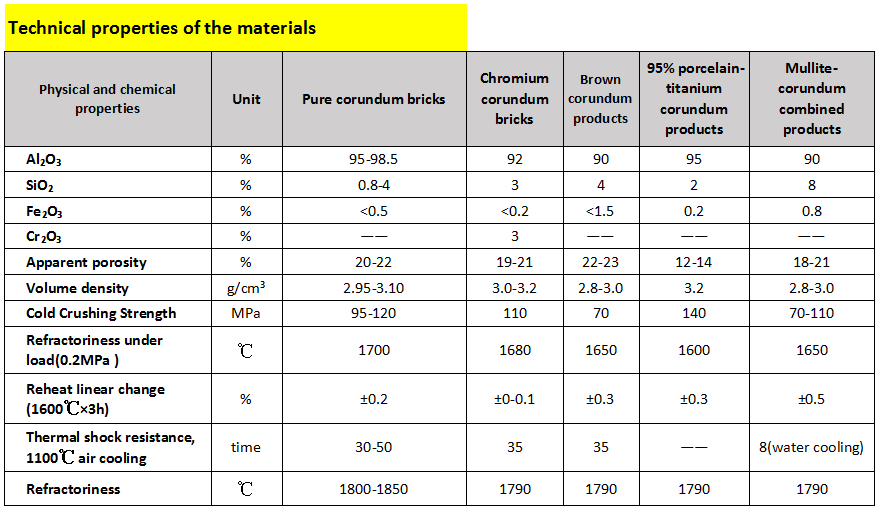

Above data is theoretical value

•Pure corundum bricks are made of super fine powders of aluminum oxide, corundum and selected electro-melted corundum through high-pressure formation and sintering. These bricks are featured with high purity and stable high-temperature performance.

•Chromium corundum bricks are made by adding small portion of Cr2O3 to corundum products so these bricks have improved thermal shock stability, anti-corrosion to various gases and wear-resistance.

•Brown corundum products are the result of direct combination of electro-melted corundum and super fine aluminum oxide through high temperature formation and sintering. It is a cheap corundum product with high quality and could replace pure corundum to be used in sub-burning zone.

•The launch of 95 porcelain-titanium corundum products solves the problem of the wear resistance of magnet material sintering kilns. Usually embedding rails on rail bricks would save funds and reduce the length of time for inspection and repair.

Mullite-corundum combined products

1) Load bearing bricks: featured with high purity, no reaction with magnetic products and high thermal shock resistance;

2) Used in high-temperature burners in carbon oxide and sulfur burning furnaces, featured with high thermal shock resistance and high-temperature-resistance.

•Chromium corundum bricks are made by adding small portion of Cr2O3 to corundum products so these bricks have improved thermal shock stability, anti-corrosion to various gases and wear-resistance.

•Brown corundum products are the result of direct combination of electro-melted corundum and super fine aluminum oxide through high temperature formation and sintering. It is a cheap corundum product with high quality and could replace pure corundum to be used in sub-burning zone.

•The launch of 95 porcelain-titanium corundum products solves the problem of the wear resistance of magnet material sintering kilns. Usually embedding rails on rail bricks would save funds and reduce the length of time for inspection and repair.

Mullite-corundum combined products

1) Load bearing bricks: featured with high purity, no reaction with magnetic products and high thermal shock resistance;

2) Used in high-temperature burners in carbon oxide and sulfur burning furnaces, featured with high thermal shock resistance and high-temperature-resistance.

Edit:JUNYAO

Quality-oriented

Quality-oriented