Wear-resisting refractory materials used in fluidized bed boilers

Date:2016-12-13 / Popularity:

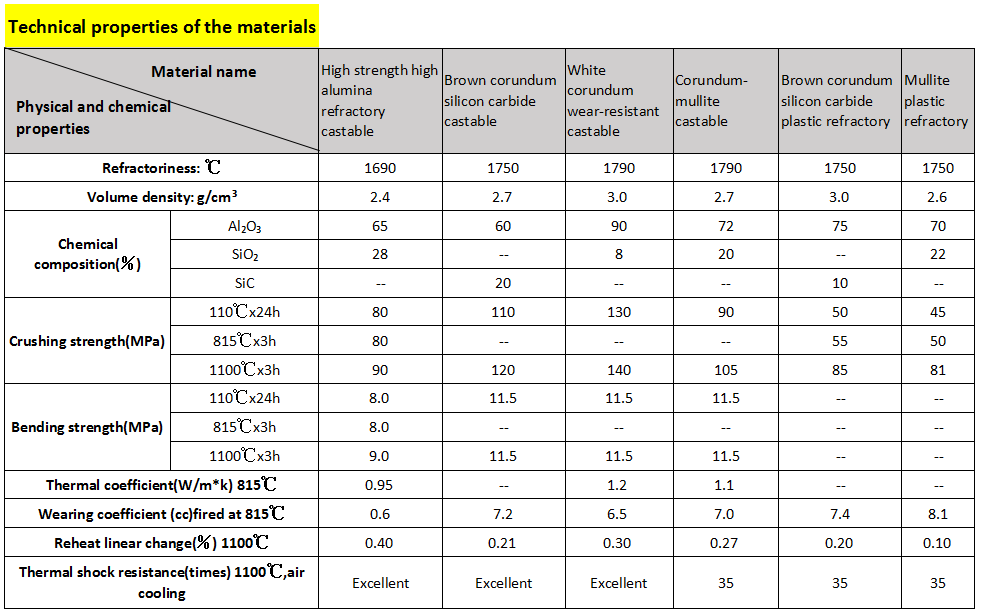

In recent years, along with the application and large-size trend development and application of circulating fluidized-bed combustion boilers in China According to the current status of wear-resistant refractory materials used for the lining of fluidized bed boilers and characteristics--middle temperature of inner lining (middle-temperature physical and chemical performance of refractory materials--strength); frequent start/stop(thermal shock performance of refractory materials--cracking and peeling off) of circulating fluidized bed boilers; high flow speed of smokes and solid flow concentration (wear-resistance of refractory materials)--of circulating fluidized beds, combining new type of refractory raw materials domestic and abroad (synthetic aggregates, super micro powders and compound binding agents), we developed these series of wear-resistant refractory materials used in each location of linings inside the boilers of circulating fluidized bed.

Above data is theoretical value

Edit:JUNYAO

Quality-oriented

Quality-oriented